Soundproofing & Acoustic Solutions for Machines

Why Soundproofing and Acoustics Are Crucial for Machines

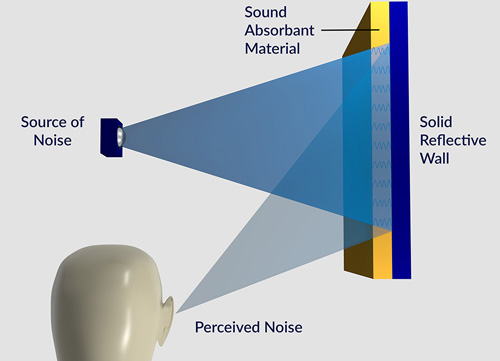

Machines and industrial equipment are essential for productivity in manufacturing plants, workshops, and operational facilities. However, they generate high noise levels, structural vibrations, and low-frequency hum, which can impact worker safety, communication, and overall operational efficiency

Effective soundproofing and acoustic treatments ensure:

Noise Reduction:

Minimize harmful noise exposure for workers.

Vibration Control:

Reduce structural noise transmission.

Regulatory Compliance:

Meet occupational noise safety standards.

Operational Efficiency:

Prevent machinery noise from disrupting nearby operations.

Enhanced Communication:

Ensure clear communication in noisy environments.

Key Areas That Require Acoustic Treatment and Soundproofing

1. Machine Enclosures

Why It Matters: Machines operating without acoustic enclosures cause significant noise pollution.

Solutions:

SoundBlanket® (4mm): Acts as a dense sound barrier to block airborne noise from machinery.

BassBloc® Sound Absorber: Controls vibrations and low-frequency noise generated by machinery operations.

Acoustic Foam Panels: Absorb internal noise within enclosures.

Outcome: Reduced noise emissions and minimized noise leaks from machinery enclosures.

2. Industrial Workshops and Factory Floors

Why It Matters: Open factory spaces often amplify noise from multiple machines running simultaneously.

Solutions:

SoundBlanket® (4mm): Create noise barriers between machinery zones.

BassBloc® Sound Absorber: Manage structural vibrations caused by heavy machinery.

Acoustic Foam Panels: Absorb excess airborne noise.

Outcome: Reduced noise levels for workers and improved operational efficiency.

3. Control Rooms and Monitoring Stations

Why It Matters: Noise from machinery can interfere with monitoring and communication systems.

Solutions:

SoundBlanket® (4mm): Isolate control rooms from factory floor noise.

BassBloc® Sound Absorber: Eliminate vibrations traveling through walls and floors.

Acoustic Fabrics: Add additional sound absorption for improved clarity.

Outcome: Quiet monitoring environments for accurate data analysis and clear communication.

4. Generator Rooms and Heavy Machinery Zones

Why It Matters: Generators and large machinery produce loud, low-frequency sounds that travel through walls and floors.

SoundBlanket® (4mm): Prevent airborne noise transmission.

BassBloc® Sound Absorber: Control vibrations and heavy bass hum.

Acoustic Foam Panels: Dampen sound reflections within generator rooms.

Outcome: Noise isolation and vibration-free operations in heavy machinery zones.

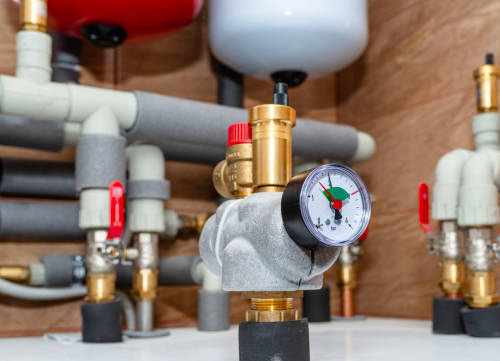

5. HVAC and Air Compression Units

Why It Matters: Noise from air compressors and HVAC systems can disrupt nearby operations.

Solutions:

SoundBlanket® (4mm): Block noise leaks from compressor units.

BassBloc® Sound Absorber: Dampen mechanical vibrations effectively.

Acoustic Foam Panels: Absorb ambient machine noise.

Outcome: Quiet HVAC operations with minimal acoustic disruption.

Common Mistakes in Machine Soundproofing and Acoustics

Ineffective Noise Control

These mistakes lead to ineffective noise control, regulatory violations, and increased worker fatigue and dissatisfaction.

How MMTPL Products Solve These Challenges

1. SoundBlanket® (4mm):

Acts as a high-density noise barrier to block airborne machinery noise.

Ideal for machine enclosures, generator rooms, and HVAC systems.

Compliant with ASTM E-84 and ASTM C423 standards.

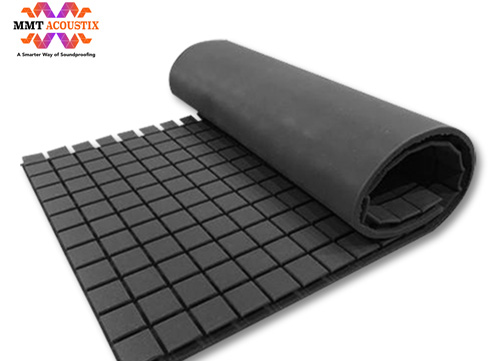

2. BassBloc® Sound Absorber

Targets low-frequency noise and structural vibrations from machinery and heavy equipment.

Prevents resonance from transferring through walls and floors.

Suitable for industrial floors, walls, and enclosures.

3. Acoustic Foam Panels

Lightweight and effective for absorbing high-frequency machine noise.

Suitable for machine enclosures, walls, and control rooms.

4. Acoustic Fabrics

Provide an additional layer of sound absorption while maintaining durability.

Suitable for control rooms and industrial spaces requiring aesthetic finishes.

Maximized Performance, Reduced Costs, and Efficient Installation

Reduced Machinery Noise:

Minimized airborne and structural noise emissions.

Vibration-Free Structures:

Controlled structural resonance from heavy equipment.

Worker Safety:

Compliance with industrial noise safety standards.

Improved Communication:

Clear conversations in noisy environments.

Cost-Effective Solutions:

Durable materials designed for industrial use.

Quick Installation:

Efficient setup with minimal operational disruption.

Certified Products:

Backed by ASTM-compliant testing for performance and safety.

Why Choose MMTPL for Machine Acoustics?

Customized Industrial Solutions:

Tailored soundproofing for different machinery types.

Certified Products:

Compliant with ASTM E-84, ASTM C423, and ASTM E90 standards.

Durable Materials:

Long-lasting products designed for heavy-duty environments.

Professional Consultation:

Expert recommendations for optimized solutions.

Proven Experience:

Successful soundproofing across manufacturing plants, workshops, and industrial facilities.

Applications in Machinery Acoustics:

Machine Enclosures:

Noise barriers and vibration control for enclosed systems.

Factory Floors:

Noise isolation between machinery zones.

Control Rooms:

Quiet spaces for monitoring and operations.

Generator Rooms:

Minimized generator hum and structural noise.

HVAC and Air Compressors:

Controlled airborne and mechanical noise.

Conclusion

At MMTPL, we understand the critical need for noise control and vibration management in industrial environments. Our SoundBlanket®, BassBloc®, Acoustic Foam Panels, and Acoustic Fabrics provide effective, durable, and certified solutions to reduce noise, eliminate vibrations, and improve worker safety.

MMTPL – Where Every Decibel is Controlled, and Every Machine Runs Silently