Sound Insulation Pad (SIP)

The Sound Insulation Pad (SIP) is a polyurethane-based sound absorber crafted from high-density acoustic foam, specifically designed to deliver exceptional sound absorption performance. With an impressive NRC (Noise Reduction Coefficient) of 0.80 at a thickness of 25mm, this sound insulation pad excels in absorbing mid and high-frequency sounds, making it an ideal choice for various acoustic applications. Engineered for versatility, SIPs are widely used behind perforated ceiling and wall panels to significantly enhance NRC ratings and improve overall acoustic performance.

Additionally, they are highly effective for soundproofing machine canopies, offering reliable noise control in industrial settings.

Available in both UL 94 Fire Standard Class HS1 (fire-resistant) and Non-FR (Non-Fire-Resistant) versions, SIPs cater to diverse application requirements, ensuring flexibility and compliance with safety standards.

Why Choose Sound Insulation Pad (SIP)?

The Sound Insulation Pad (SIP) offers unparalleled sound absorption capabilities with a remarkable NRC of 0.80, even at a modest thickness of 25mm. With its ability to excel in mid and high-frequency absorption, compatibility with perforated panels, and effectiveness in industrial machine canopies, SIP is the go-to solution for both architectural and industrial acoustic requirements.

Sound Insulation Pad – Precision Absorption, Unmatched Acoustic Comfort.

Key Benefits

• High NRC Rating: Delivers an NRC of 0.80 at 25mm thickness, offering excellent sound absorption.

• Mid & High-Frequency Absorption: Superior performance in controlling noise in critical frequency ranges.

• Versatile Applications: Suitable for use behind perforated wall and ceiling panels and in machine canopies.

• Customizable Thickness: Available in thicknesses ranging from 10mm to 750mm.

• Fire Safety Options: Available in both UL 94 Fire Standard Class HS1 and Non-FR variants.

• Standard Size: Available in 6x3 feet (1.8x0.9m) dimensions.

• Durable & Long-Lasting: Resistant to wear, moisture, and degradation over time.

• Easy to Install: Lightweight and flexible, allowing seamless installation in various spaces.

Applications

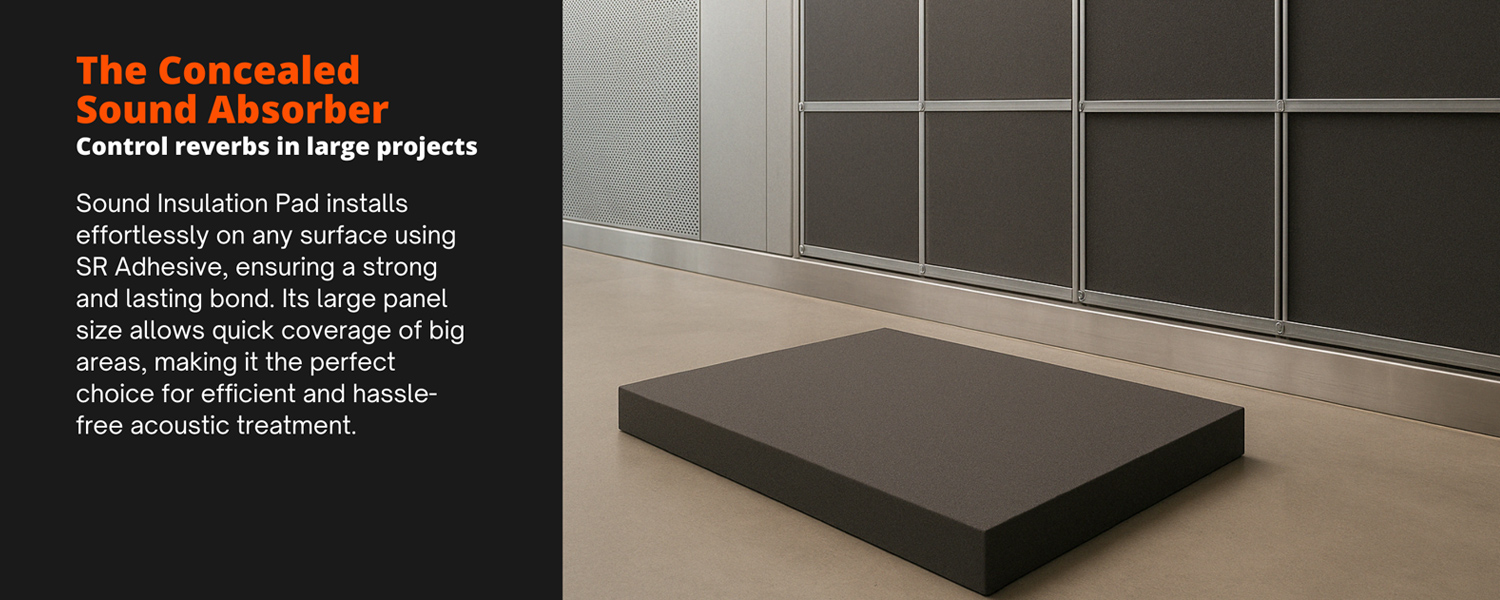

• Behind Perforated Panels: EInstalled behind perforated ceilings and walls to enhance NRC ratings and acoustic performance.

• Machine Canopies: Noise control in industrial machinery enclosures to minimize sound leakage.

• HVAC Systems: Used in duct linings and ventilation systems for noise dampening.

• Recording Studios: Enhances sound clarity and reduces noise reflections.

• Auditoriums & Theaters: Improves sound absorption and prevents unwanted reverberation.

• Home Theaters: Optimizes acoustics for a high-quality sound experience.

• Educational Spaces: Controls noise levels in classrooms and lecture halls.

Installation Guide:

• Measure the Area: Assess the space and cut the pad to the required dimensions.

• Surface Preparation: Ensure the mounting surface is clean and dry.

• Apply Adhesive: Use acoustic adhesive for secure placement behind panels or on machine surfaces.

• Mount the Pad: Install directly behind perforated wall or ceiling panels or inside machine enclosures.

• Seal Gaps: Use acoustic sealant to eliminate potential sound leaks.

• Inspect and Finish: Ensure the pad is securely in place and functioning as intended.

Material:

High-Density Polyurethane Acoustic Foam

Standard Size:

6x3 feet (1.8 x 0.9m)

Thickness Range:

10mm to 750mm

NRC (Noise Reduction Coefficient):

0.80 at 25mm thickness

Frequency Performance:

Optimal absorption in mid and high-frequency ranges

Fire Rating:

UL 94 Fire Standard Class HS1 (Fire-Resistant) & Non-FR versions available

Installation Method:

Suitable for direct mounting, adhesive application, or use with perforated panels